Kevin Stanyer, Custom Fabrication Manager, talks about his role at BC Greenhouses.

When it comes to custom greenhouses, Kevin is an amazing resource for the team at BCG. The custom projects that are designed and manufactured from his department are unique, complex and quite frankly cool. But let’s go back to the beginning for a moment.

Kevin started with BCG in 1999. Interestingly for me, he also came as a recommendation from Centra Windows.

“I was going to go work for Centra but the position wasn’t available quite yet,” Kevin says. Centra Windows and BC Greenhouse Builders have a long history of friendship and hockey camaraderie.

Kevin is pictured front center

“You didn’t have a typical construction background before you started here?” I ask surprised. Kevin previously acted as Operations Supervisor for Value Village and did some construction.

“I worked for Parklane as a labourer for a while and I learned a lot from my brother. I was always really good in school with woodworking and drafting and I can visualize things easily,” he says.

“I think it’s fair to say you have a specific acumen; a special skill when it comes to fabricating. Is it true that you don’t often use a calculator for designing?” I ask.

“I use a calculator but a lot of it is in my head. I use it more these days because my brain’s getting old and it’s just faster to add multiple rows of numbers together,” he chuckles. “I play with CAD a lot these days too. (Computer Aided Design software). I draw everything nowadays because I need to share the sizes and components with several fabricators and a picture is a thousand words,” Kevin says.

Kevin's custom Santa village fabricated with opal twinwall polycarbonate

But where did it all start? “I started in glass, poly and caps and worked through all the stations and within two years I was pretty much doing custom jobs,” he says. That’s quite a trajectory. “I think working on Sonora Resort was one of my first custom jobs.”

“Do you marvel at the level of projects that are going out the door these days?”

“Yes, but I want them bigger,” Kevin says with a determined look.

“What do you consider small?” Apparently anything less than 20 feet wide and 36 feet long!

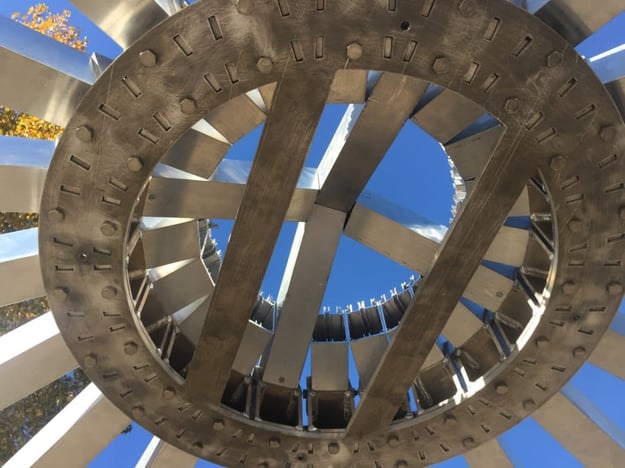

Do you have a favourite project? “The dome,” he says with certainty. This was a circular curved skylight made with tubular curves. It was incredibly custom and 20 feet in diameter. Given that it is located on the roof of a large property, we don’t have many specific photos other than from Google Earth and the engineered drawings but it gives you a sense of the complexity. “Everything was so precise with that job. It was up and installed in two days.”

The Dome. A tubular skylight which is 20 feet in diameter.

.jpg?width=625&height=479&name=Southbrook-1024x785%20(1).jpg)

Rick Heinen, owner of BC Greenhouse Builders, has worked with Kevin for decades now. “I have always enjoyed working with Kev over all these years. He has been great for our company, moving our custom greenhouses to a whole new level. He loves the jobs that push the BCG envelope!”

Kevin on his work anniversary with Rick Heinen

"You’ll like my new project I’m starting in January,” Kevin says. I perk up. “It’s a pyramid. 30 by 30 and 25 feet tall. I’ll be standing it up in my shop. There is a recessed door because there will be a pyramid within a pyramid. It’s going to be really cool.” Mental note to self: take photos!

Kevin has travelled quite a bit for installs too. Iceland seems the most remote although Florida is technically farther away. I ask what projects were a game changer for BCG. He mentions P.S. 216 in Brooklyn New York. It’s an interesting reverse slope fivewall polycarbonate greenhouse that was designed by WorkAC in conjunction with The Edible Schoolyard. That project has thankfully introduced us to several other school greenhouses in the area including an L-shaped greenhouse that will be installed soon.

P.S. 216 Edible Schoolyard Greenhouse in Brooklyn, NY

“What’s the future look like for you? More rooftop greenhouses like the Drakestone Conservatory?”

“Yes, Dallas was a cool looking project. Those photos look awesome. I wish it was helicoptered down Main Street though,” he says with a smile. I’m not sure that he’s even kidding with me.

The Drakestone Conservatory in Dallas

I ask about favourite memories. “I liked those days when I would go up to Rod’s house in Kelowna for a week or two to fab a project and sleep on the couch with his dog,” he laughs.

How do you attribute the growth the last few years? “Our salespeople are amazing and we have a lot of them now. And our dealers are doing amazing and they are big projects too.”

We talk a bit more about trends and family and he mentions that both of his children have helped out here as well. Kevin and his wife Leanne are parents to Hunter aged 22 and Lily aged 20 who are both attending post-secondary studies. “Lily helped out with the Iceland job prepping the greenhouses for install. She’s currently taking biology and archaeology. Hunter has been great on installs and prepping jobs too. He’s studying astronomy and computer science.” It’s not a surprise that Kevin’s kids have helped out as these interviews always have a way of circling back to family. BCG is made up of so many people with their skills and talents and we are so grateful for it. Big thanks to Kevin for taking the time for this interview and for sharing his history and vision. We are a better company because you are here Kevin. Here’s to the next 20 years!